What is ReJIT

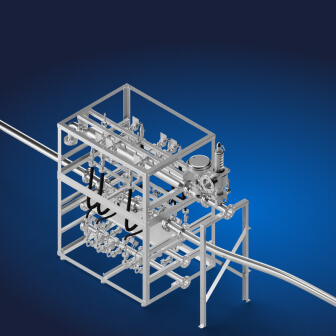

ReJIT can be installed and put into operation without any intervention in the production line and produces paraffin in nano sizes, providing high cost savings. The paraffin it produces, due to its physical properties, provides the target water absorption resistance values with much lower paraffin consumption.

While ReJIT reduces the amount of paraffin used in the production line where it is put into use, it also indirectly provides savings in paraffin supply and storage processes.

ReInventing the Wheel

Those who know us know that no matter how deep-rooted a methodology is, we question it. Innovation starts with the courage to question the truth that is thought to be unchangeable. We began to question some of the open points that had been on our radar for a while about the decades-old industry methods of producing wood-based panels.

60% of paraffin supplied in emulsion form is water. Do we have to carry water?

The paraffin used for water absorption resistance prevents the glue used for mechanical resistance from holding on to the wood fibers. How can the interaction of these two indispensable active ingredients be better managed?

What is the smallest paraffin particle size that can be achieved consistently and consistently?

The storage life of the paraffin emulsion is limited. Can the shelf life of paraffin be extended?

Is there a way to control the fluctuation experienced in paraffin quality and particle size, which also affects production quality and costs?

Is there a way to eliminate logistics and storage problems by getting the right amount of paraffin on the production line just in time?

New Invention: ReJIT

After a long persistent inquiry process, we created ReJIT as a revolutionary solution for paraffin processes in wood-based panel production.

JIT: Just In Time

ReJIT is an in-house system which allows you to produce the highest quality emulsion containing nano size paraffin, just in time.

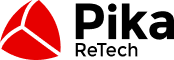

So how does it work?

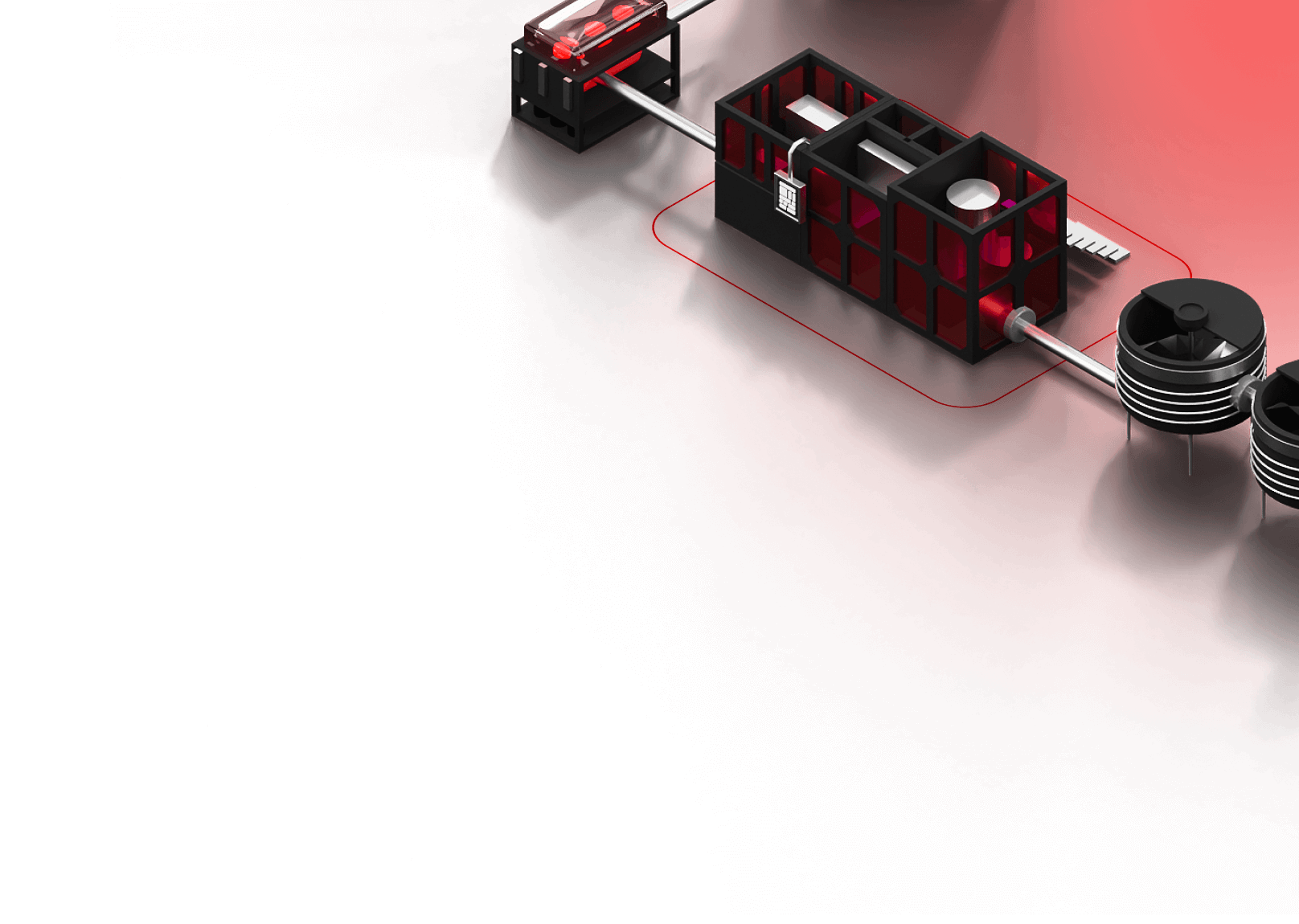

In its simplest terms, the ReJIT system consists of 3 basic processes.

The Input

The input for ReJIT basically consists of solid paraffin or paraffin emulsion and additives. The paraffin emulsion formation may vary depending on the production facility. The only condition is that the paraffin emulsion to be placed in the ReJIT tank conforms to the predefined values. After including other additives, required by production, along with the paraffin emulsion in the ReJIT tank, the process can be initiated by transferring into the buffer tank.

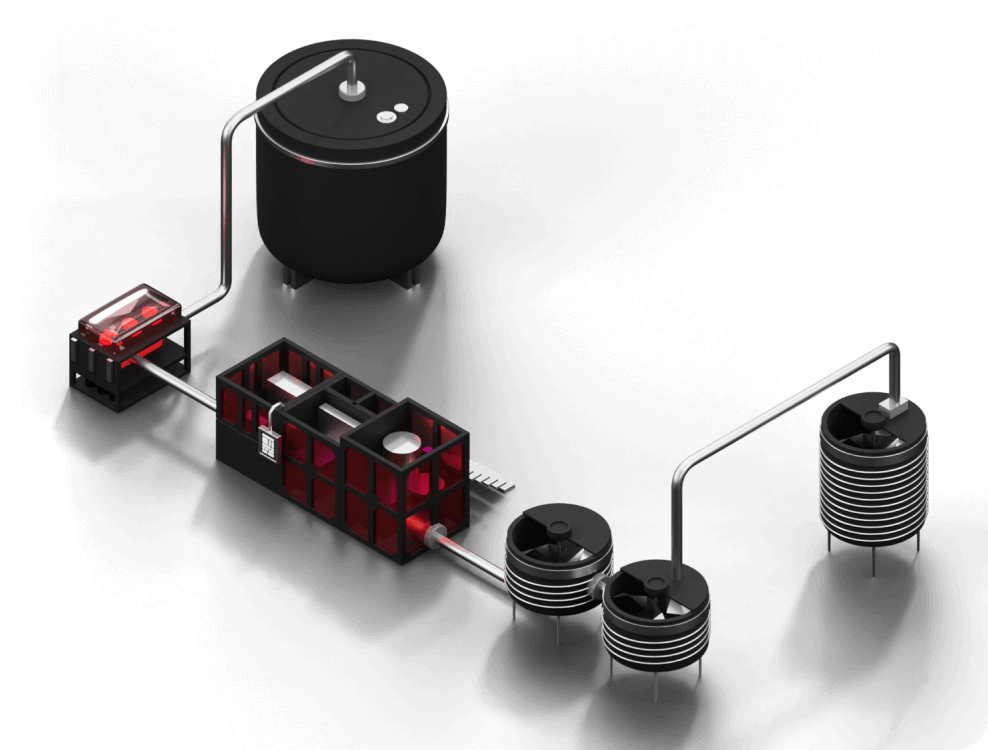

The Magic

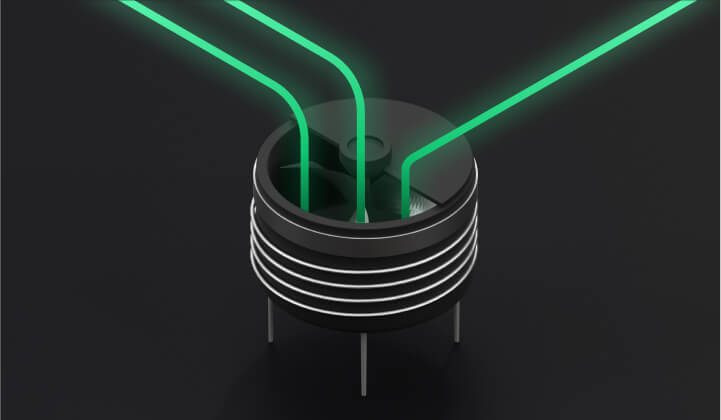

The pre-prepared mixture entering ReJIT is converted into nano particles with Pika ReTech technology. This is the part where the magic happens. This magic is the product of a system that works according to the principles of fluid mechanics. Curious minds can look into the second law of thermodynamics and the elegance of entropy to appreciate the magic. With the fluid resistance created in ReJIT, the paraffin is divided into nano-sized pieces and transmitted to the cooling line after all particle surfaces are covered perfectly.

The Output

The nano paraffin emulsion produced is cooled to ideal temperature values and transferred to the storage tank. The paraffin solution is now ready to be used. Paraffin produced with ReJIT can be stored for long periods of time since there are no shelf life limitations. However, it is recommended to produce paraffin on demand and feed the line continuously.

Sustainability

The ReJIT system by Pika ReTech exemplifies a sustainable approach to wood-based panel production, addressing a multitude of challenges that have plagued the industry for decades.

By enabling on-site, just-in-time production of nano-sized paraffin, ReJIT significantly reduces the need for transportation and storage, ultimately minimizing the overall carbon footprint. In addition, the reduction in paraffin usage due to its nano-sized particles leads to higher cost savings for customers, as well as reduced waste generation.

Moreover, ReJIT's ability to extend the shelf life of paraffin and maintain consistent quality and particle size further contributes to sustainability by ensuring reduced waste and optimal resource utilization. This innovative technology allows for better management of the interaction between paraffin and glue, resulting in increased efficiency and reduced environmental impact.

By integrating ReJIT into their production lines, customers can not only improve their operational efficiency but also align with sustainable practices, enhancing their brand reputation and contributing to global conservation efforts.

Connect With Us

Reach out to us for any inquiries, assistance, meeting requests, or to learn more about the company and our innovative products and how they can benefit your business.

Thank you

Your message has been sent successfully. We will reach you as soon as possible.