Reinventing the Wheel

When examining the wood-based panel production process in detail from beginning to end, it can be seen that there are processes and methods that have not been considered, designed, questioned, and need to be reviewed again. Proper questioning leads to the right solution.

Can the paraffin-glue interaction be improved, and can their mutual dampening effects be prevented?

What can be done to reduce the sanding allowance of wood-based panels?

Is there a way to reduce formaldehyde emission values in wood-based panels?

Can the widely used separation process in the industry be developed to solve other problems that have been overlooked and considered unsolvable so far?

Can improvements be made during the pressing stage to extend the life of the line?

Are the losses that seem inevitable during the pressing and sanding stages truly unavoidable?

How can improvements be made in existing wood-based panel production processes without disrupting the workflow or requiring significant equipment changes?

New Invention: ReBoost

By scrutinizing the entire wood-based panel production process, we identified unexplored areas for improvement and developed groundbreaking solutions.

The ReBoost product family is already addressing numerous industry challenges, and our vision is to continue expanding the product range to cover every aspect of the production process.

Release Agent

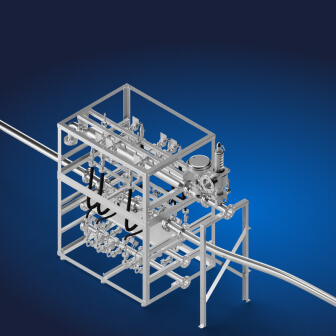

ReBoost 500 is an environmentally friendly, water-based additive that extends the life of the production line by reducing contact with the composite surface. Easy to apply and cost-effective, it is suitable for all types of wood products and can be used in both multi-layer and continuous press systems. Start with a 3% water dilution, which can be adjusted down to 1% depending on the type of wood used.

Panel Performance Enhancer

ReBoost 725 is a surface performance additive that reduces the adverse effects of paraffin and glue, increases mechanical and water absorption resistance, and improves swelling and strength values. It also has exceptional release agent properties, eliminating the need for additional release agents. A 3-5% diluted solution can be applied at 8-20g/m2, with increased effectiveness as the application amount rises.

Surface Performance Enhancer

ReBoost 942 is a high-performance surface additive that minimizes the pyrolysis of wood fibers and carbonization of the glue, reducing the sanding margin. It also has exceptional release agent properties, eliminating the need for additional release agents. ReBoost 942 is 100% active and water-free, with an ideal application amount of 0.8-1.2 g/m2, depending on wood type and process conditions. Offering a high price-to-performance ratio, this specialized surface performance enhancer is a valuable addition to any production process.

Formaldehyde Scavenger

ReBoost 415 is a highly effective additive for absorbing free formaldehyde and reducing formaldehyde emission values in wood-based panels. Its specialized formula absorbs formaldehyde, resulting in significantly lower emission levels. During application, a 5-9% mixture with wet glue should be prepared, ensuring that the standard hardener amount and gel time are controlled. Minor pressure adjustments may be required, but no significant process changes are needed. ReBoost 415 offers an excellent cost-benefit ratio as a successful and high-quality formaldehyde scavenger.

Sustainability

The ReBoost product family not only offers innovative solutions for optimizing wood-based panel production but also delivers tangible sustainability benefits for manufacturers. By using ReBoost additives, manufacturers can achieve the following sustainability gains:

Reduced Resource Consumption: Our products, such as ReBoost 725, decrease the consumption of paraffin and glue, leading to more efficient use of resources and reduced waste in the production process.

Extended Equipment Lifespan: ReBoost 500, ReBoost 725 and ReBoost 942 products extend the life of production lines, reducing the need for frequent equipment replacement and minimizing the environmental impact of manufacturing.

Lower Formaldehyde Emissions: ReBoost 415 effectively captures and reduces formaldehyde emissions, contributing to improved indoor air quality and a healthier living environment for end-users.

Improved Energy Efficiency: By minimizing the pyrolysis of wood fibers and carbonization of glue, ReBoost 942 reduces the sanding margin, leading to a more energy-efficient production process and lower energy consumption overall.

By incorporating ReBoost products into your wood-based panel production process, you not only optimize efficiency and performance but also contribute to a more sustainable and responsible manufacturing approach.

Connect With Us

Reach out to us for any inquiries, assistance, meeting requests, or to learn more about the company and our innovative products and how they can benefit your business.

Thank you

Your message has been sent successfully. We will reach you as soon as possible.