What is ReFogger

ReFogger breaks down the glue that will meet with wood fibers by steam, forming maximum surface area and minimum particle size, and injects it into the blowline, ensuring target mechanical strength values with minimum glue consumption.

ReInventing the Wheel

We have some doubts about the insufficiency of the methods applied in the industry for decades regarding glue consumption, one of the highest cost items in wood-based panel production.

Are the common application methods taking the characteristics of the used resin into account enough?

How can the mechanical strength that the same amount of resin will provide to the same amount of wood fibers be increased by changing which parameters?

What other methods can be used to break down the resin and increase the surface area, and which method provides the highest breakdown performance?

Can the glue breaking system be isolated?

Which feature of the resin provides mechanical strength?

What is the mathematics of the correlation between the surface area of wood fibers and the surface area of glue particles?

What are the blowline forces that affect the glue breaking process in common methods?

New Invention: ReFogger

ReFogger is a new system that emerged by asking questions about traditional and common glue systems, and it provides targeted mechanical strength values with minimum glue consumption based on patented technology with particle and fluid physics principles.

So how does it work?

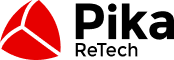

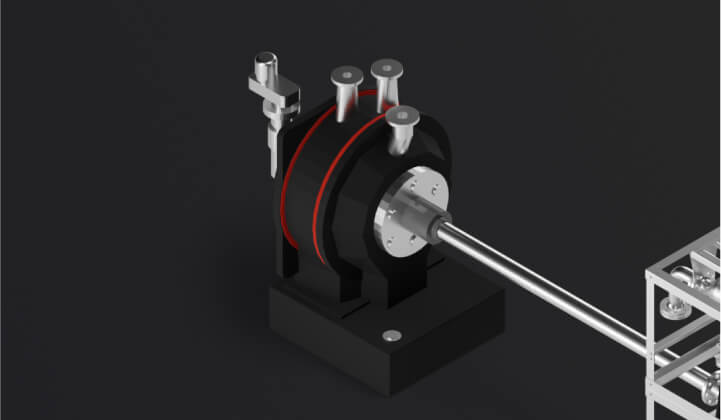

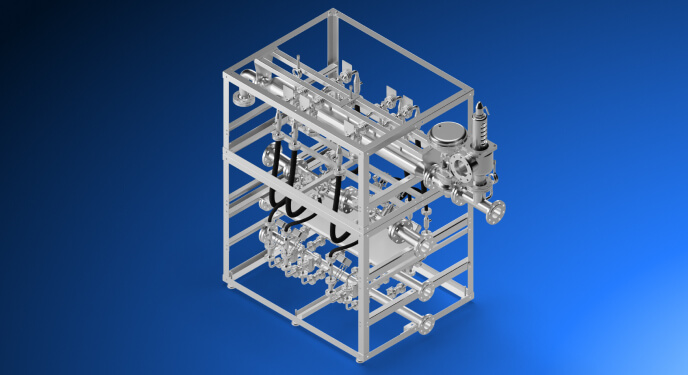

In its simplest terms, the ReFogger system consists of 3 basic processes.

The Input

ReFogger uses resin and steam as input. It is sufficient to connect it to the resin and steam feed of the production line it is activated on. ReFogger performs the ideal consumption, pressure and flow controls with its own hardware and software systems. Once the necessary installation and adjustments are made, the system can be started.

The Magic

The explosion room is the area where ReFogger takes its basic inputs and performs its magic. In this area, the glue is separated into ideal-sized particles with the correct pressure and flow rate. The reason for the success of ReFogger seeming like magic is that it can create the smallest resin particle sizes possible by simply processing the basic rules of fluid physics, without requiring any complex additional hardware or mechanisms. This system has the aesthetic of a Judo move where the opponent's energy is used against them. The continuation of the magic occurs in the blowline where the glue is transferred.

The Output

The resin, which is separated into particles of the ideal size for mechanical strength, is included in the blowline. ReFogger ensures the homogeneous distribution of resin particles on wood fibers with the turbulence created by the S-shaped blowline module. The smallest possible size of resin particles and the homogeneous distribution in the S blowline ensure that maximum surface area is covered with minimum resin.

Sustainability

ReFogger has achieved unparalleled success in the industry with the mechanical strength values it provides per unit of consumption.

ReFogger has provided the wood industry with an indispensable sustainability advantage.

When considering the carbon footprint of the resin usage, which the wood industry is dependent on for mechanical strength, ReFogger is of vital importance to the world.

For all companies operating in the wood industry, reducing their resin usage rates to the values provided only by ReFogger at the moment will result in tremendous savings in global glue consumption.

Versions

ReFogger Plug-in

ReFogger Plug-in is a modularly integrated version of the glue saving system. It fills the glue saving gap in the existing system with a plug and play concept. It integrates with all the functions and instruments of your glue saving system and develops its capabilities with ReFogger's patented technology to provide maximum mechanical strength values with minimum glue consumption. ReFogger Plug-in is an ideal Pika ReTech solution for lines that are already a glue saving system and are not planning to be replaced in the near future.

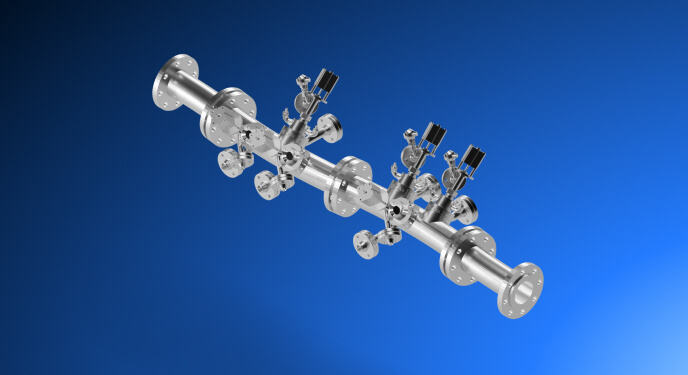

ReFogger Ace

ReFogger Ace is an end-to-end glue saving system. All the functions and instruments necessary to run the patented ReFogger technology with the highest efficiency and safety values have been encapsulated by Pika ReTech in an automation system. ReFogger Ace is an ideal Pika ReTech solution for new lines, lines without a glue saving system, or those who want to replace their existing glue saving system.

Features

Real - time Reporting and Alarm System

Distribution Control System

Advanced Optimization System

Runtime Analytics System

Continuous Pressure Optimization System

Self Cleaning System

Fail-safe Boot System

Real - time Reporting and Alarm System

Distribution Control System

Advanced Optimization System

Runtime Analytics System

Continuous Pressure Optimization System

Self Cleaning System

Fail-safe Boot System

Connect With Us

Reach out to us for any inquiries, assistance, meeting requests, or to learn more about the company and our innovative products and how they can benefit your business.

Thank you

Your message has been sent successfully. We will reach you as soon as possible.