ReInventing the Wheel

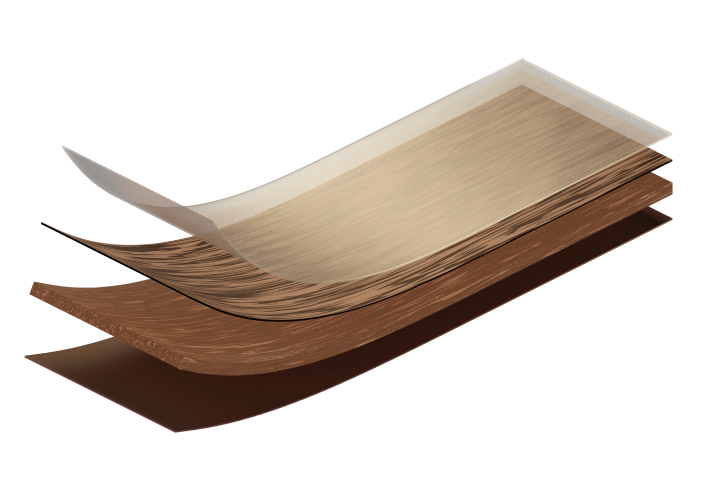

Aluminum oxide, an industry-standard material, is supplied in powder form and applied to the overlay paper or decorative paper during the impregnation stage. We began questioning the commonly used aluminum oxide material and its processing methods in the industry.

Which property of aluminum oxide exactly provides wear resistance?

What values should be considered for optimization?

Are there optimization opportunities during the processing?

Is it possible to save while maintaining the highest wear resistance?

Does the material hardness cause any side effects during the production process?

Can ideal ratios be achieved with a controlled processing method?

Are there any losses that increase side effects without providing wear resistance benefits, and can these losses be minimized?

New Invention: ReFlot

The answers to these questions paved the way for a new Pika ReTech innovation. ReFlot (Front Line of Own Troops) was developed in Pika ReTech laboratories as an aluminum oxide product that minimizes material usage while maximizing surface area protection in laminate flooring products and reduces side effects in the production line.

ReFlot is produced with three rules in grinding machines designed by Pika ReTech, addressing the fundamental problems of traditional aluminum oxide production and application methods in laminate flooring production.

ReFlot consists of rounded aluminum oxide particles

ReFlot is produced in a wide range of nano, micro, and macro particles by processing in the Pika ReTech grinding machine

ReFlot is classified as nano particles below 63 microns, macro particles above 125 microns, and micro particles at 75, 90, and 106 microns after passing through a two-stage screening process.

Features

Minimum Waste & Maximum Strength

The shape and size of the aluminum oxide particles used are the most critical factors determining durability and, consequently, consumption. ReFlot consists entirely of rounded aluminum oxide particles. Rounded particles minimize the detachment of particles from the surface when exposed to impacts. The ready-to-use ReFlot product consists of 85-90% aluminum oxide particles between 75-120 microns. Particles below 63 microns have a very low contribution to surface strength. ReFlot, consisting of round and 75-120 micron aluminum oxide particles, provides savings of up to 30%.

Safe Production and Cost Savings

Particles above 120 microns can cause damage to the boards during the pressing stage. Since 90% of ReFlot particles are below 120 microns, it extends the life of the press plate. ReFlot is a purpose-designed aluminum oxide product. With ideal particle shape and size, it offers up to 30% savings in material usage. No money is spent on particles that do not contribute to strength or damage production since 85-90% of particle sizes are precisely controlled. ReFlot provides a strategic advantage in addition to the extra cost advantage by minimizing the damage of aluminum oxide particles to the press plate, reducing the need to stop the production line during press plate replacement.

Sustainability

ReFlot's innovative design contributes to sustainability in laminate flooring production. By utilizing rounded aluminum oxide particles with ideal size and precision, it enables manufacturers to reduce material consumption by up to 30%. This decreased consumption translates to reduced waste generation, a more efficient use of resources, and ultimately, a smaller environmental footprint. Additionally, the longer lifespan of press plates due to minimized damage from ReFlot particles leads to less frequent replacements, further promoting responsible resource utilization and waste reduction. In essence, ReFlot supports a more sustainable approach to laminate flooring production by enhancing efficiency, lowering costs, and minimizing the industry's overall environmental impact.

Connect With Us

Reach out to us for any inquiries, assistance, meeting requests, or to learn more about the company and our innovative products and how they can benefit your business.

Thank you

Your message has been sent successfully. We will reach you as soon as possible.